Line Boring

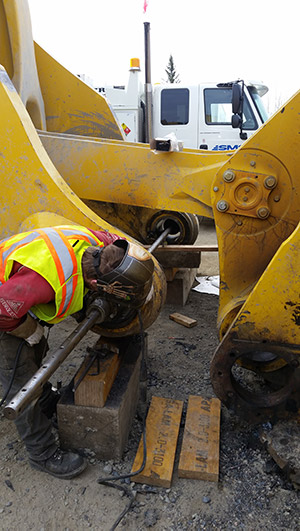

No matter what industry you are in, if your equipment has moving parts, chances are there are bores that simply must be in line for the machine to operate properly. It is common to find that bearing bores are worn from years of operation – even when the machine has been properly maintained. The simple fact is that well designed and properly maintained machines that operate day after day, year after year eventually need to be restored in order to operate properly.

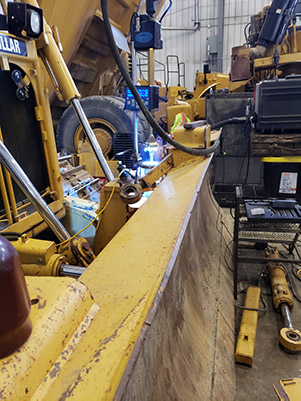

For the last 15 years, Ryan Casper at IMS has perfected the technique of line boring. We have the equipment and the support equipment to get the job done as fast as possible and more importantly still provide a great quality product. We have a fully equipped enclosed trailer which is mobile. We have the York Smart Welder to build bores quickly and efficiently which also provides a much better weld.

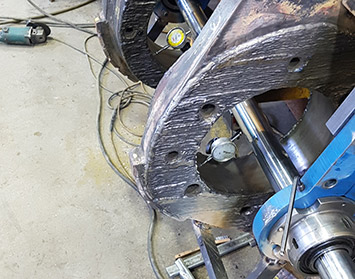

IMS owns a York Portable line boring machine and bore welder to complete any of your line boring needs. We recently added the BB5000 portable climax boring machine to handle the bigger bores on larger machines. IMS has had the privilege to use the largest boring bar in the climax rental fleet the BB8100. This bar has great potential for the very large inside diameters, flanges and outside diameter turning.

Here is a list of just a few items we have line bored:

Small and large excavators, wheel loaders, dozers, wicket gate pockets in a hydroelectric power facility, Komastu 6500 bucket exactor, Komastu WA 1200 wheel loader, coupling bolts for a turbine shaft and turbine, turbine blade bolt holes, rock trucks, massive gearboxes, ladle turret arms, and much more.

With the help of a local precision laser company PFTS, we have designed and tested a system that is able to cut the time of machining the wicket gate bottom bore in the situ from weeks to only days. We have completed this process on over a dozen hydro facilities.

Contact us for your line boring needs! We will bore and hone them to precise sizing and alignment!

Gallery